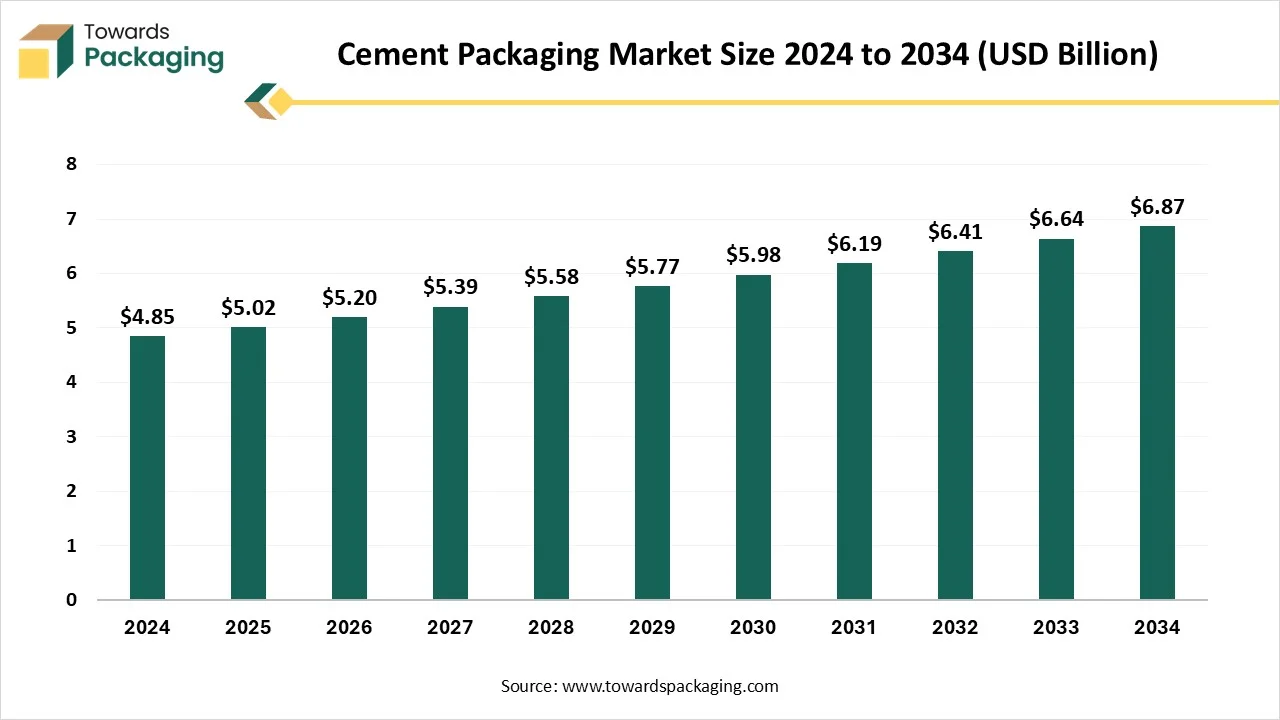

Ottawa, Nov. 05, 2025 (GLOBE NEWSWIRE) -- The cement packaging market size surpassed USD 4.85 billion in 2024 and is estimated to hit around USD 6.87 billion by 2034, growing at a CAGR of 3.55% from 2025 to 2034. The cement packaging market is witnessing steady growth, driven by expanding construction and infrastructure development worldwide. The shift toward eco-friendly, durable, and cost-efficient packaging materials further enhances the region’s dominance in the global market, a study published by Towards Packaging, sister firm of Precedence Research.

Request Research Report Built Around Your Goals: sales@towardspackaging.com

What is meant by cement packaging?

The cement packaging market is driven by rapid construction growth, urbanization, and increasing demand for efficient, moisture-resistant, and eco-friendly packaging solutions. Cement packaging refers to the process of enclosing and protecting cement products using materials such as paper bags, plastic bags, or jute sacks to ensure safe handling, transportation, and storage. It plays a crucial role in preventing cement from exposure to moisture, air, and contamination, which can affect quality and strength.

Modern cement packaging focuses on durability, cost-effectiveness, and sustainability, with innovations like multi-wall paper bags and recyclable polymer films improving product integrity and reducing environmental impact. Asia-Pacific leads the market due to rapid urbanization, large-scale housing projects, and government investments in smart cities and industrial zones. Countries such as China, India, and Indonesia are major contributors, supported by high cement production volumes and sustainable packaging demand.

What are the Major Government Initiatives for the Cement Packaging Industry?

- Mandatory Quality Control Orders (QCOs): The Ministry of Chemicals and Fertilizers has mandated that woven sacks for packaging cement meet specific Bureau of Indian Standards (BIS) quality norms to ensure public safety and product integrity.

- Co-processing of Plastic Waste: Guidelines issued by the Central Pollution Control Board (CPCB) promote using cement kilns to safely dispose of and co-process plastic waste, which reduces environmental impact.

- Performance, Achieve, and Trade (PAT) Scheme: This initiative under the Ministry of Environment, Forest, and Climate Change targets energy-intensive industries, like cement, to improve energy efficiency and reduce emissions.

- Infrastructure Development: Large-scale government projects, such as the Pradhan Mantri Awas Yojana and the PM Gati Shakti Master Plan, increase demand for cement, thereby boosting the packaging industry.

- Make in India Initiative: This broader program encourages domestic manufacturing and innovation, promoting the production of quality packaging materials within the country and boosting the cement industry's capacity and exports.

Get All the Details in Our Solutions - Access Report Sample: https://www.towardspackaging.com/download-sample/5865

What Are the Latest Key Trends in The Cement Packaging Market?

- Sustainable & Eco-Friendly Materials: Manufacturers increasingly adopt paper sacks, biodegradable bags and recyclable films to reduce environmental impact and meet regulatory mandates. This shift enhances brand value and aligns packaging with green construction initiatives.

- Automation & Smart Packaging Technologies: New packaging lines feature automation form-fill-seal machines, valve bags plus smart tools like RFID tags and QR codes that track shipments and counter counterfeit cement. Efficiency and traceability are key gains.

- Moisture-Resistant and Performance-Enhanced Designs: To protect cement’s quality, packaging now uses multi-wall paper with liners or heavy-duty plastic bags offering superior barrier against humidity and physical damage during transport/storage.

- Packaging as Brand Differentiation: With more retail-bagged cement, brands use high-quality printing, customized bag sizes, and visible packaging features to stand out on shelves and build consumer trust in crowded markets.

What is the Potential Growth Rate of the Cement Packaging Industry?

Technology Advancement & Rising Demand for Sustainable Packaging

Technological advancements and the rising demand for sustainable packaging are major forces driving the growth of the market. Innovations such as automated filling systems, multi-wall paper sacks, and moisture-resistant polymer coatings improve durability, reduce leakage, and enhance operational efficiency during storage and transport. These technologies ensure minimal material wastage and improved handling efficiency.

Simultaneously, the shift toward eco-friendly and recyclable packaging materials like biodegradable paper bags and compostable films aligns with global sustainability goals and stricter environmental regulations. Cement manufacturers are increasingly adopting such solutions to reduce their carbon footprint and enhance brand reputation. This combination of smart technology integration and green packaging initiatives is reshaping the cement packaging industry, promoting long-term growth and environmental responsibility.

Limitations & Challenges

Stringent Environmental Regulations & Limited Recycling Infrastructure

The key players operating in the market are facing issues due to limited recycling infrastructure and stringent environmental regulations. Growing global restrictions on plastic usage and carbon emissions are pressuring manufacturers to shift from traditional plastic or woven polypropylene bags to sustainable materials, which often raise production costs. In many developing regions, inadequate recycling and waste management systems hinder large-scale adoption of eco-friendly cement packaging solutions.

More Insights of Towards Packaging:

- North America Automotive Thermoformed Plastic Parts Packaging Market

- Asia Pacific Food Packaging Market Growth, Key Segments, and Regional Dynamics

- Europe Pharmaceutical Packaging Market Growth, Key Segments, and Regional Dynamic

- Europe Flexible Packaging Market Size, Segments, Companies, Competitive Analysis

- North America Pharmaceutical Packaging Market Growth, Key Segments

- North America Post-Consumer Recycled Plastics Food Packaging Market Growth

- Europe Transfer Molded Pulp Packaging Market Size, Share, Trends, Segments

- Europe Food Packaging Market Growth, Key Segments, and Regional Dynamic

- U.S. Beverage Packaging Market Size, Segments, Regional Data

- U.S. Rigid Packaging Market Size, Segments, Companies, Competitive Analysis

- Germany E-Commerce Packaging Market 2025 Outlook Plastic Leads

- U.S. 503B Compounding Pharmacy Packaging Market Size and Insights

- U.S. 503A Compounding Pharmacy Packaging Market Size and Insights

- Nano Enabled Packaging Market Transformed by AI

- Reusable Transport Packaging Market Gains Global Momentum

Regional Analysis:

Who is the leader in the Cement Packaging Industry?

The Asia-Pacific region leads the market due to rapid industrialization, large-scale construction projects, and strong demand for infrastructure development. Countries like China, India, Indonesia, and Vietnam are experiencing extensive urban expansion, driving high cement consumption and packaging needs. Government initiatives such as India’s Smart Cities Mission and China’s Belt and Road Initiative further boost cement demand.

Additionally, the presence of major cement producers, availability of low-cost raw materials, and technological advancements in packaging solutions such as moisture-resistant paper bags and recyclable polypropylene sacks, enhance the region’s dominance. Rising environmental awareness and a shift toward sustainable, lightweight packaging materials also support long-term market leadership for Asia-Pacific in the global cement packaging sector.

What are the Ongoing Trends in the Chinese Market?

China dominates the regional market due to its massive construction industry, continuous urbanization, and government investments in infrastructure and housing. The country’s focus on eco-friendly and high-strength packaging materials, along with automation in cement bag manufacturing, strengthens its leadership and drives steady market expansion.

What are the India Cement Packaging Market Trends?

India’s market growth is fuelled by rapid urbanization, large infrastructure projects like Smart Cities and affordable housing schemes, and rising cement production capacity. Increasing adoption of sustainable paper and polypropylene packaging, coupled with expanding domestic manufacturing capabilities, enhances India’s strong position in the Asia-Pacific market.

What are the new Trends in the Japan Cement Packaging Market?

Japan’s market benefits from advanced packaging technology, strict environmental standards, and demand for high-quality, recyclable materials. The country’s focus on innovation, automation, and efficient material handling systems supports premium cement packaging solutions, promoting sustainability and precision in construction and infrastructure development projects.

What is the opportunity in the Rise of North America in the Cement Packaging Industry?

The North America region is the fastest-growing in the market due to rising infrastructure renovation projects, sustainable construction practices, and technological innovation in packaging materials. Increased demand for recyclable and moisture-resistant paper sacks, coupled with the region’s strong focus on carbon reduction and automated packaging systems, supports market expansion across the U.S. and Canada.

What are the New Trends in the U.S. Cement Packaging Market?

The U.S. leads the North American market, driven by major infrastructure modernization, housing demand, and sustainability goals. Increasing adoption of recyclable paper and polypropylene cement bags, along with automated filling and sealing technologies, enhances packaging efficiency and supports the nation’s transition toward environmentally responsible construction practices.

What are the Latest Trends in the Canada Cement Packaging Market?

Canada’s market growth is supported by expanding urban development, government investments in green infrastructure, and growing demand for moisture-resistant and biodegradable packaging materials. The country’s emphasis on sustainable building solutions, coupled with strong environmental regulations, encourages innovation in eco-friendly cement packaging and strengthens domestic manufacturing capabilities.

How Big is the Success of the Europe Cement Packaging Industry?

Europe is growing at a notable rate in the market due to its strong focus on sustainability, circular economy initiatives, and strict environmental regulations promoting recyclable and biodegradable packaging. Advancements in paper-based and moisture-resistant sack designs, along with increased renovation projects across Western and Central Europe, further accelerate regional demand and innovation.

How Crucial is the Role of Latin America in the Cement Packaging Market?

Latin America is growing at a considerable rate in the market due to rapid urbanization, rising housing demand, and increasing government investments in infrastructure. Countries like Brazil and Mexico are embracing cost-effective and durable packaging solutions, while growing awareness of sustainable materials encourages the adoption of eco-friendly paper and polypropylene cement bags.

How Big is the Opportunity for the Growth of the Middle East and Africa Cement Packaging Industry?

The Middle East and Africa region presents significant growth opportunities in the market due to rapid infrastructure expansion, large-scale construction projects, and rising investments in smart cities and urban development. Countries like the UAE and Saudi Arabia are adopting durable, moisture-resistant, and eco-friendly cement packaging solutions, supported by government sustainability goals and growing regional cement production.

Elevate your packaging strategy with Towards Packaging. Enhance efficiency and achieve superior results - schedule a call today: https://www.towardspackaging.com/schedule-meeting

Segment Outlook

Material Type Insights

What made the Plastics Segment Dominant in the Cement Packaging Market in 2024?

The plastic segment dominates the market due to its superior durability, moisture resistance, and cost-effectiveness. Polypropylene and polyethylene bags offer excellent strength and protection during handling and transportation. Their reusability, lightweight nature, and compatibility with automated filling systems make them a preferred choice among cement manufacturers worldwide.

The paper segment is the fastest-growing in the market due to increasing demand for sustainable, biodegradable, and recyclable materials. Strict environmental regulations and rising awareness of eco-friendly construction practices are driving manufacturers to shift from plastic to multi-wall paper cement bags.

Capacity Insights

How did the 21 kg to 50 kg dominate the Cement Packaging Market in 2024?

The 21 kg to 50 kg segment dominates the market as it aligns with standard industrial and construction requirements for convenient handling, storage, and transportation. Widely preferred by both commercial and residential builders, this capacity range ensures cost efficiency, easy manual loading, and compatibility with automated filling systems, making it the most practical and in-demand packaging size globally.

The 6 kg to 20 kg segment is the fastest-growing in the market due to rising demand from retail and small-scale construction projects. Its lightweight, easy-to-handle packaging format caters to do-it-yourself (DIY) consumers and urban renovation needs, promoting convenience, reduced wastage, and improved product accessibility in emerging and developed markets.

Product Type Insights

Which Product Type Dominated the Cement Packaging Market in 2024?

The cement bag segment dominates the market due to its widespread use in bulk and retail cement distribution. Offering durability, moisture protection, and easy handling, cement bags especially paper and polypropylene types ensure efficient storage, transport, and cost-effective packaging solutions, making them the preferred choice among manufacturers and contractors.

The sacks segment is the fastest-growing product type in the market due to its cost-effectiveness, lightweight nature, and high durability. Increasing adoption of multiwall paper and woven polypropylene sacks for efficient bulk handling and enhanced moisture protection drives their demand, especially across emerging construction and infrastructure projects.

Recent Breakthroughs in Global Cement Packaging Industry

- On June 30 2025, Klabin showcased its Ekomix dispersible paper cement bags and Ekolayer plastic-free barrier technology at ExpoCimento while emphasizing renewable and recyclable packaging solutions. The Ekomix dispersible paper cement bags and Ekolayer plastic-free barrier technology are the cement packaging developed from 100% dispersible paper.

- In July 2025, UltraTech Cement won the “Responsible Packaging” award for using cement bags made from 50% recycled polypropylene (rPP), achieving a 43% reduction in virgin plastic usage at FIPSA 2025. This event was organized by the Foundation for Innovative Packaging and Sustainability (FIPS).

- In June 2024, Mondi launched the SolmixBag, a one-ply paper bag made from 100% kraft paper, designed to disintegrate in the cement mixer, reducing waste on construction sites. Mondi has launched these solutions with its partner Cemex.

Top Companies in the Cement Packaging Market & Their Offerings:

Tier 1:

- Uflex Ltd: Uflex provides high-strength, waterproof, woven polypropylene (WPP) bags, known as "SafePack," for cement packaging, designed to prevent spillage, clotting, and moisture ingress while offering high-quality branding options.

- Bischof + Klein SE & Co. KG: This company offers a range of industrial packaging solutions for the construction industry, including highly-ventilatable and sift-proof cross-bottom valve sacks and FFS (form-fill-seal) films made from 100% recyclable PE.

- Mondi Group: Mondi is a leading supplier of paper-based cement packaging, notably the "SolmixBag," a water-soluble paper bag designed to eliminate packaging waste and reduce dust on construction sites by allowing the entire bag to be placed into the mixer.

- LC Packaging International BV: LC Packaging specializes in flexible transport packaging, including high-quality WPP bags and FIBCs (big bags) suitable for the safe and reliable transportation of dry bulk construction materials like cement.

- Gascogne SA: Gascogne offers industrial bags, including paper sacks, for powdery materials like cement, focusing on durability and performance during the filling, storage, and transport processes.

- Smurfit Kappa Group: Smurfit Kappa primarily focuses on paper-based and corrugated packaging solutions for consumer goods, and while their general portfolio is vast, they may offer containerboard or heavy-duty paper sacks suitable for industrial materials.

- Hood Packaging Corporation: Hood Packaging manufactures a variety of industrial bags, including multiwall paper bags and plastic packaging solutions for construction materials, known for strength and weather resistance.

- Berry Global, Inc.: Berry Global produces engineered flexible and rigid packaging solutions, including heavy-duty sacks and films that can be used for industrial powders like cement, emphasizing performance and protection.

- Sonoco Products Company: Sonoco offers diverse packaging solutions, including a range of industrial paper and plastic bulk bags designed to protect products like cement during storage and transportation.

- United Bags: This company is a supplier of various types of industrial bags, including woven polypropylene and multiwall paper bags, which are suitable for packaging bulk materials such as cement.

- Taurus Packaging: Taurus Packaging produces multi-wall paper sacks and woven polypropylene bags specifically tailored for the demanding requirements of packaging cement and other building materials.

Tier 2:

- NNZ Group

- ToolAsia Polysacks Pvt. Ltd

- TolAsian Polysacks Pvt. Ltd

- Gulf Paper Manufacturing Co.

- Storsack Group

- Rosenflex UK Ltd

- Asia Packaging Industries Ltd

- Fujian Henglong Plastic Industry Co., Ltd

- Unisun Packaging

Tier 3:

- Elsepack

- Shalimar Pack

- Flexipol Packaging Ltd

- Orient Sacks Pvt. Ltd

- BulkSack India Pvt. Ltd

- Packwell Industries

- Taurus Polymers Pvt. Ltd

- Qingdao BagKing Packaging Co., Ltd

Global Cement Packaging Market

By Material

- Plastics

- Paper

- Jute

By Capacity

- Up To 5kg

- 6kg To 20kg

- 21kg To 50kg

- Above 50kg

By Product Type

- Bags

- Pouches

- Sacks

- Others

By Region

- North America:

- U.S.

- Canada

- Mexico

- Rest of North America

- South America:

- Brazil

- Argentina

- Rest of South America

- Europe:

- Western Europe

- Germany

- Italy

- France

- Netherlands

- Spain

- Portugal

- Belgium

- Ireland

- UK

- Iceland

- Switzerland

- Poland

- Rest of Western Europe

- Western Europe

- Eastern Europe

- Austria

- Russia & Belarus

- Türkiye

- Albania

- Rest of Eastern Europe

- Asia Pacific:

- China

- Taiwan

- India

- Japan

- Australia and New Zealand,

- ASEAN Countries (Singapore, Malaysia)

- South Korea

- Rest of APAC

- MEA:

- GCC Countries

- Saudi Arabia

- United Arab Emirates (UAE)

- Qatar

- Kuwait

- Oman

- Bahrain

- South Africa

- Egypt

- Rest of MEA

Invest in Our Premium Strategic Solution: https://www.towardspackaging.com/checkout/5865

Request Research Report Built Around Your Goals: sales@towardspackaging.com

About Us

Towards Packaging is a global consulting and market intelligence firm specializing in strategic research across key packaging segments including sustainable, flexible, smart, biodegradable, and recycled packaging. We empower businesses with actionable insights, trend analysis, and data-driven strategies. Our experienced consultants use advanced research methodologies to help companies of all sizes navigate market shifts, identify growth opportunities, and stay competitive in the global packaging industry.

Stay Connected with Towards Packaging:

- Find us on Social Platforms: LinkedIn | Twitter | Instagram

- Subscribe to Our Newsletter: Towards Sustainable Packaging

- Visit Towards Packaging for In-depth Market Insights: Towards Packaging

- Read Our Printed Chronicle: Packaging Web Wire

- Get ahead of the trends – follow us for exclusive insights and industry updates:

Pinterest | Medium | Tumblr | Hashnode | Bloglovin | LinkedIn – Packaging Web Wire - Contact: APAC: +91 9356 9282 04 | Europe: +44 778 256 0738 | North America: +1 8044 4193 44

Our Trusted Data Partners

Precedence Research | Statifacts | Towards Healthcare | Towards Automotive | Towards Food and Beverages | Towards Chemical and Materials | Towards Consumer Goods | Towards Dental | Towards EV Solutions | Nova One Advisor | Healthcare Webwire | Packaging Webwire | Automotive Webwire | Nutraceuticals Func Foods | Onco Quant | Sustainability Quant | Specialty Chemicals Analytics

Towards Packaging Releases Its Latest Insight - Check It Out:

- Shrink Packaging Market Size, Segments, Share and Companies

- Sustainable E-commerce Packaging Market Booms

- Interactive Packaging Market Insights, Forecast and Competitive Strategies

- Microwave Packaging Market Scenario Planning & Strategic Insights for 2034

- Material-Neutral Packaging Market Growth Drivers, Challenges and Opportunities

- Sustainable Pharmaceutical Packaging Market Growth

- Paperboard Packaging Market Research, Consumer Behavior, Demand and Forecast

- Consumer Goods Packaging Market Drives at 5.44% CAGR (2025-34)

- North America Insulated Packaging Market Growth Drivers

- Bioengineered Packaging Market Key Trends, Disruptions and Strategic Imperatives

- Sterile Medical Paper Packaging Market Trends, Growth, and Market Size

- U.S. Personalised Packaging Market Performance, Trends

- Direct-to-consumer (DTC) Packaging Market Business Drivers & Industry Forecast

- Disappearing Packaging Market Trends, Challenges & Strategic Recommendations

- Milk Packaging Market 2025 Driven by Eco-Friendly Trends

- Mobile Phone Packaging Market Strategic Analysis & Growth Opportunities

- Woven Plastic Packaging Market Research Insight